Simple, robust and reliable. Siwa plate filter presses are applicable both in small treatment plants and in multiple industrial processes. We provide different plate sizes, pressures, lengths and materials, according to each need.

Advantages

- Simple, Reliable and Robust Equipment

- High Degree of Dehydration

- Easy Maintenance

- Low Energy Consumption

- Possibility of Automating the Entire Operation

- Easy to Regulate According to Each Application

- Low Reagent Consumption

- Large Filtration Surfaces in Little Space

Wide Range of Application

- Dehydration of Industrial or Municipal Sludge

- Liquid – Solid Separation

- Mining, Metallurgy, Ceramics

- Chemistry, Drinking Water, Pharmaceuticals, Petroleum

- Food, Oil, Breweries, Wine

- Quarries and Gravel Pits

- Special Applications. Custom Designs

- Others

Different types of Plates according to each requirement

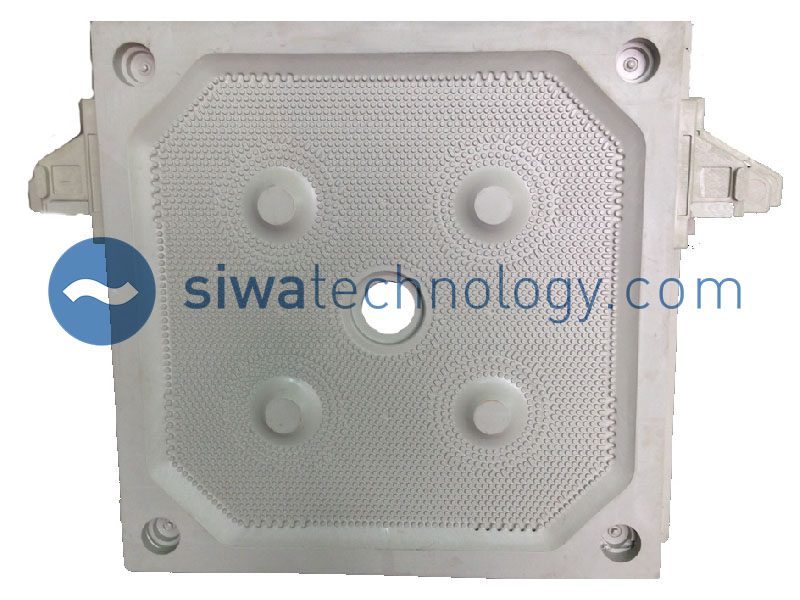

Chamber Plates

Simples, robustos y confiables. Los filtros prensa de placas Siwa, son aplicables tanto en pequeñas plantas de tratamiento, como a múltiples procesos industriales. Proveemos diferentes tamaños de placas, presiones, longitudes y materiales, acorde a cada necesidad.

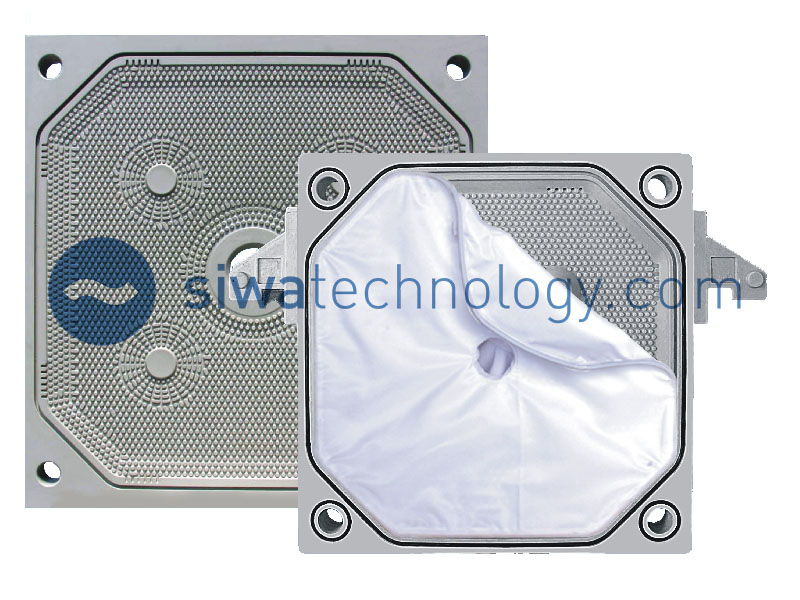

Membrane Plates

Membrane plate filters use compressed air or pressurized water to achieve additional dewatering at the end of the filtering process, increased productivity and maximum process flexibility.

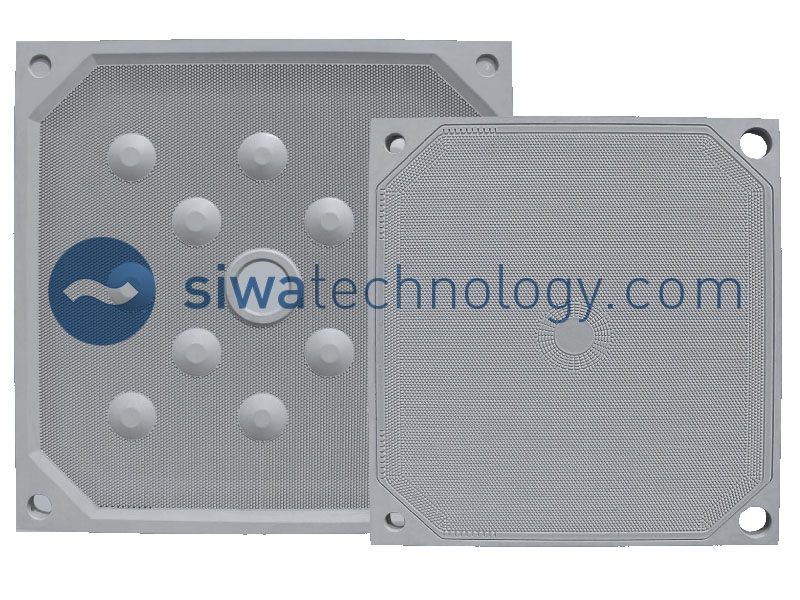

CGR Plates with Gaskets

They provide a Hermetic Closure, avoiding contact of the product with the environment and/or waste of the filtered liquid.

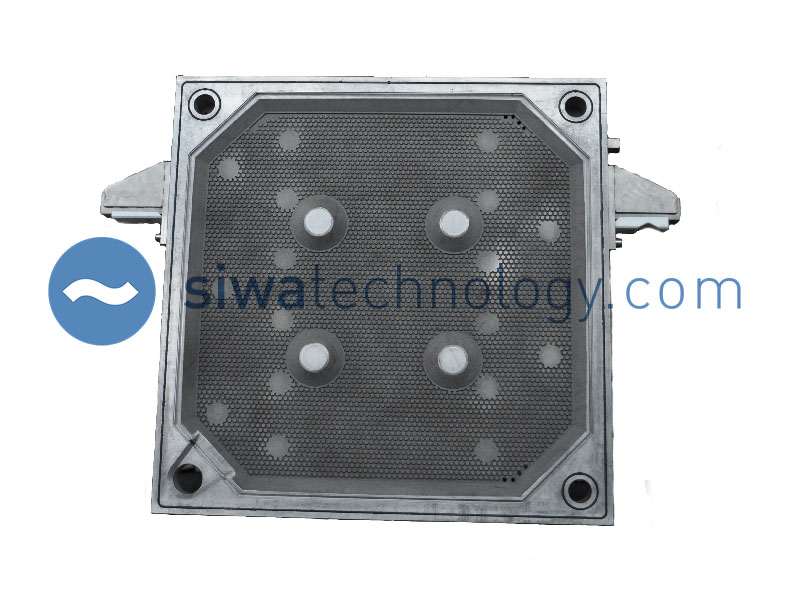

High pressure plates

Sistema de presurización de membranas por aire comprimido o agua a presión, que permite reducir la humedad de las tortas una vez concluido el proceso de filtrado estándar.

Stainless Steel Plates

For high temperature and pressure applications. Recommended for sanitary use and cases where greater chemical resistance is required. Available in AISI 304 and AISI 316.

Different Configurations and Additionals

- Automatic Plate Transport and Change System: Avoiding the Intervention of Operators and Providing Greater Control.

- Drain Membrane Inflation System for Greater Dehydration

- Automatic or Manual Hydraulic Power Plant

- Quick Plate Opening System

- Completely Closed, Watertight or Open Execution with or without Drip Collection Tray

- Washing and/or Blowing Cakes after the Filtering Process

- Automatic Fabric Cleaning System

- Stainless Steel or Carbon Steel Structure with Anti-corrosion Coverage

- Equipment with Upper or Lateral Plate Transfer

- Fully Anti-Explosive Configuration for Flammable Chemicals

-

We have the Right Fabric for Each Application (We have more than 100 different fabrics)

-

Mud Feed Pumps

-

Mud Thickeners prior to the Filter Press

-

Polymer Dosing and Preparation Systems

-

Collecting Hoppers and Cake Conveyor Belts

Different types of plates according to each requirement: