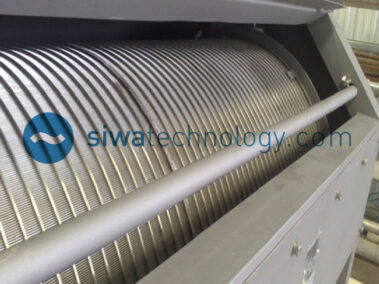

The BRS series of Siwa filters are robust and versatile equipment, recommended for cases of high flow rates with high solids contents in multiple industries. The siwa IRM Series is designed for high flow rates and low solids contents of wastewater. They are compact units and totally closed to contain vapors. The IRO series are lighter open equipment, and for more standard applications. Capacities range from 12 to 3,000 m3/h, with openings from 0.2 to 10 mm. The filter drum can be slotted with self-cleaning V-shaped profiles, perforated or mesh.

MODE OF OPERATION

The effluent enters the weir which distributes it over the interior walls of the drum. Solids are retained on the filter surface while liquid passes radially through the openings. While the liquid is conducted to the drainage area, the solids are transported axially towards the open end of the drum. The rotation of the drum allows the entire surface of the drum to be continuously or intermittently cleaned by the external bar equipped with spray nozzles.

Applications

- Municipal effluents

- Paper and Pulp

- Fishing Industry

- Meat and Chicken Processing

- Wine effluents

Advantages

- Construction in AISI 304/316

- Robust Structure

- Compact Design

- Exterior Spray Cleaning Bar and Inner Fins.

- TEFC Gear Motor with Stainless Steel Chain.

Optional accessories

- Screw Press Compactor / Solids Dehydrator.

- Solids Conveyor Screw.

- Feed pump

- Agitator

- Level Sensor

- Solids Discharge Hopper.

- frequency converter

- Gradual Openings along the Drum

- Centralized lubrication system

- Additional cleaning nozzles on the inside of the drum

- Piping to/from other equipment.a